NICHROME FILMS: Nichrome vs Aluminum

Aluminium is the most popular metal used in metallized films; it has a versatile, low-cost and stable metal (slow oxidation) for making window films. In the past decade, Nichrome is also emerging as a close cousin with similar cost benefits and outlook. Nichrome provides a longer oxidation durability and better heat reduction than Aluminium. It is now used in these signature products:

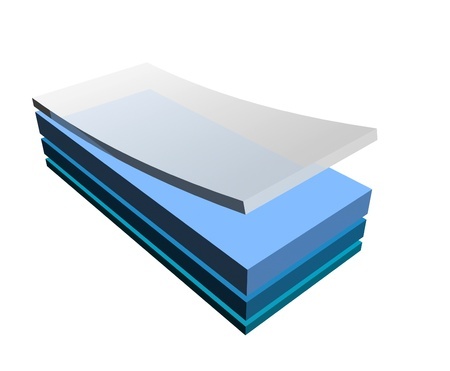

- Added to multi-layer sputtered magnetron films to improve stability of sputtered silver coatings

- Most popular high-end Nichrome product : NSN Films (Nichrome-Silver-Nichrome)

- Coated via E-beam evaporation to provide superior shading coefficient at affordable prices

NON FADING FILMS: Better Fading Durability

Non-fading films are now more affordable and, nearly all US factories are now supplying non-fading automotive films. Three of the most popular technologies include:

- Extrusion-dyed Polyester: Superior durability offered by Japanese polyester makers

- Dip-dyed Polyester: Improved versions are color-stable (not likely to turn purplish)

- Carbon pigments: Added to laminating adhesive or scratch resistant coating

SIGNAL FRIENDLY: Non-Metallized + High Heat Reduction Auto Films

Metallized window films do affect telecommunication and GPS signals of devices on board our vehicles. Ceramics materials such as Titanium Nitride, Antimony Tin Oxide, Indium Tin Oxide, Carbides, Borides, etc, can be used in replacement of metals, to achieve the same level of heat reduction without interfering with electronic signals.

SAFETY AUTO FILMS: Enhanced vehicle security

Engineer your existing Automotive Films into 4MIL thickness for added protection to deter vehicle crimes. The product cost for Safety Automotive Films are only marginally higher but yet value-adds significantly to the tint package for customers.